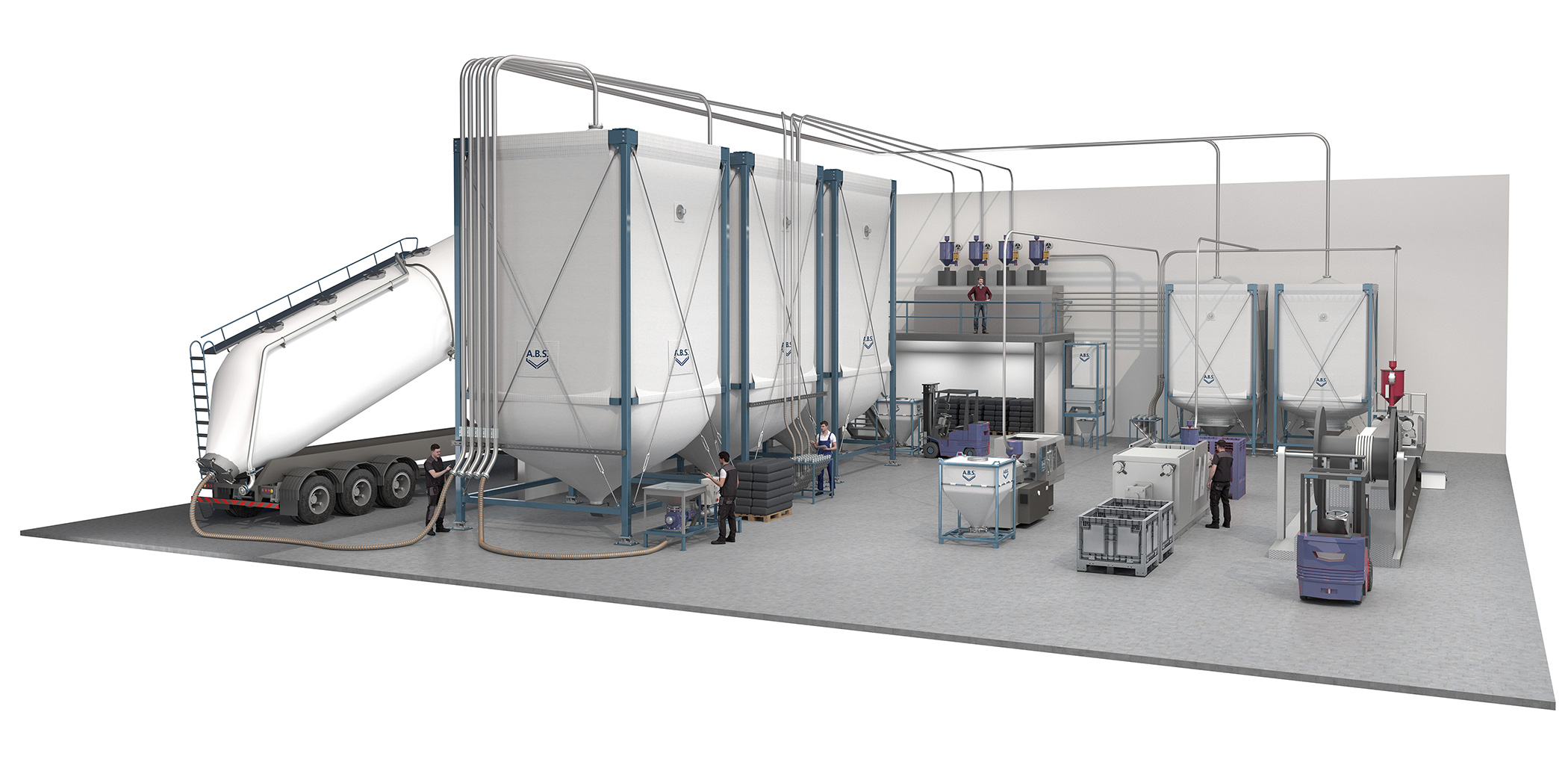

SILOS for EPS

FITS, FIT AND HAS AIR.

Plastic foams such as foamable polystyrene (EPS) and foamable polypropylene (EPP) are sensitive materials that must be stored accordingly. An inner bearing with A.B.S. is ideal for this. Flex silos.

The design and equipment of the silos – carrier fabric, cone slope, geometry, outlet diameter – are individually adapted to the respective product to be stored. Thanks to the air-permeable, breathable and permanently electrostatically dissipative polyester fabric of the silos, the foamed EPS/EPP product can stabilize and degas. In addition, the drying of the storage materials is also supported.

A.B.S. Flex silos offer a large storage capacity, up to 300 m3. Due to their enormous flexibility in size and shape, they ensure maximum use of space even when space is limited. And thanks to indoor storage, no expensive foundations or building permits are required for outdoor silos.

Highlights

- Maximum use of space, i.e. H. Large storage capacity (up to 300 m³) with little space requirement

- Low weight, therefore no complex foundations required

- High strength values and resilience: at least 7 times safer on seams and fabric – the technicians at A.B.S. On average, we expect the silos to be 12 times safer

- Permanently electrostatically dissipative polyester fabric

- Optimal leakage properties

- Can also be mounted in hard-to-reach places

- Selection of the fabric exactly according to the requirements of your EPS/EPP product

- Easy to transport and easy to install

- Can also be equipped with effective discharge aids

- No separate building permits are required for outdoor silos and no expensive foundations are required.

- In addition, the overall visual impression of the company building remains unaffected.