This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

So that everything runs perfectly.

You should definitely take this into account when planning.

Easy filling

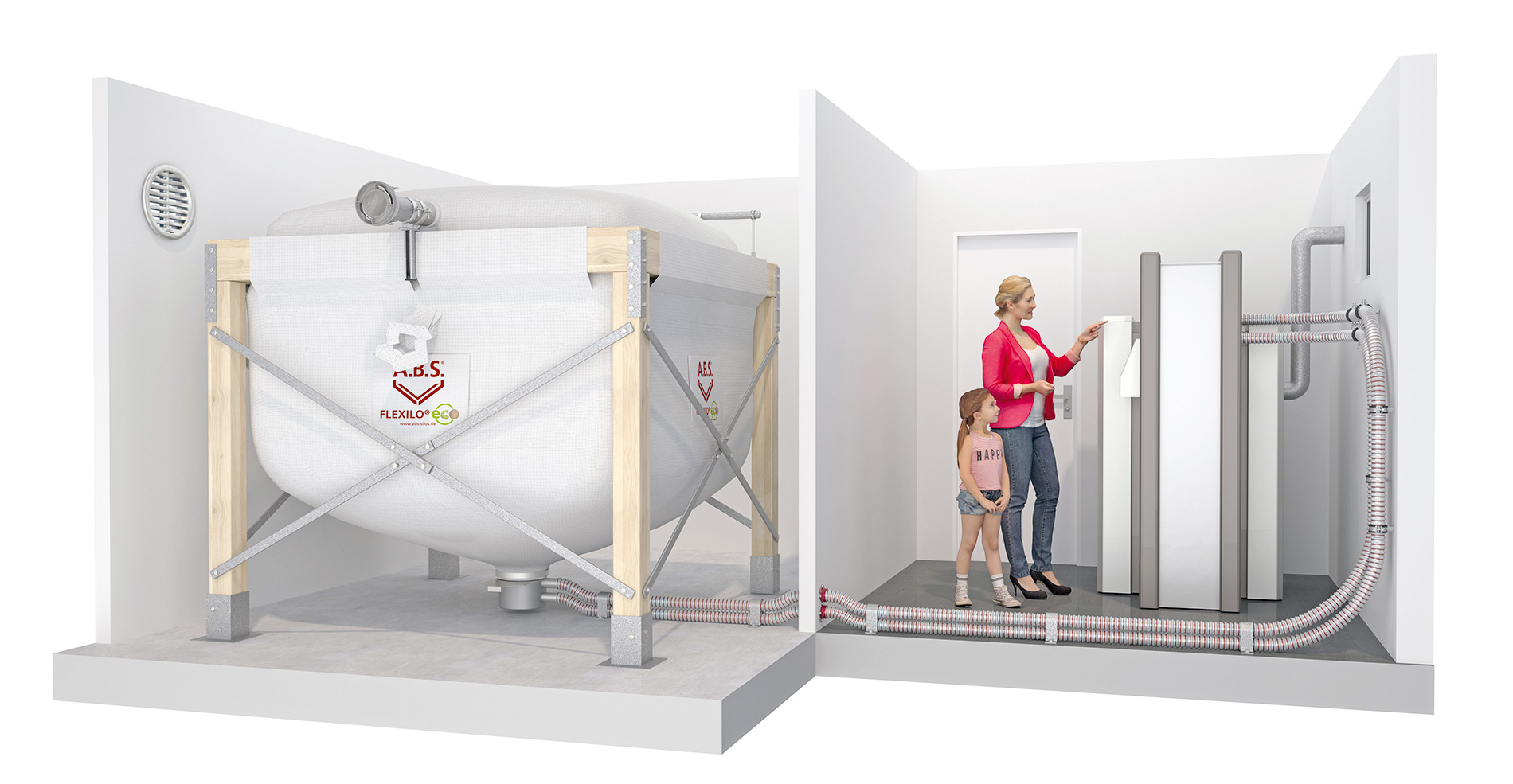

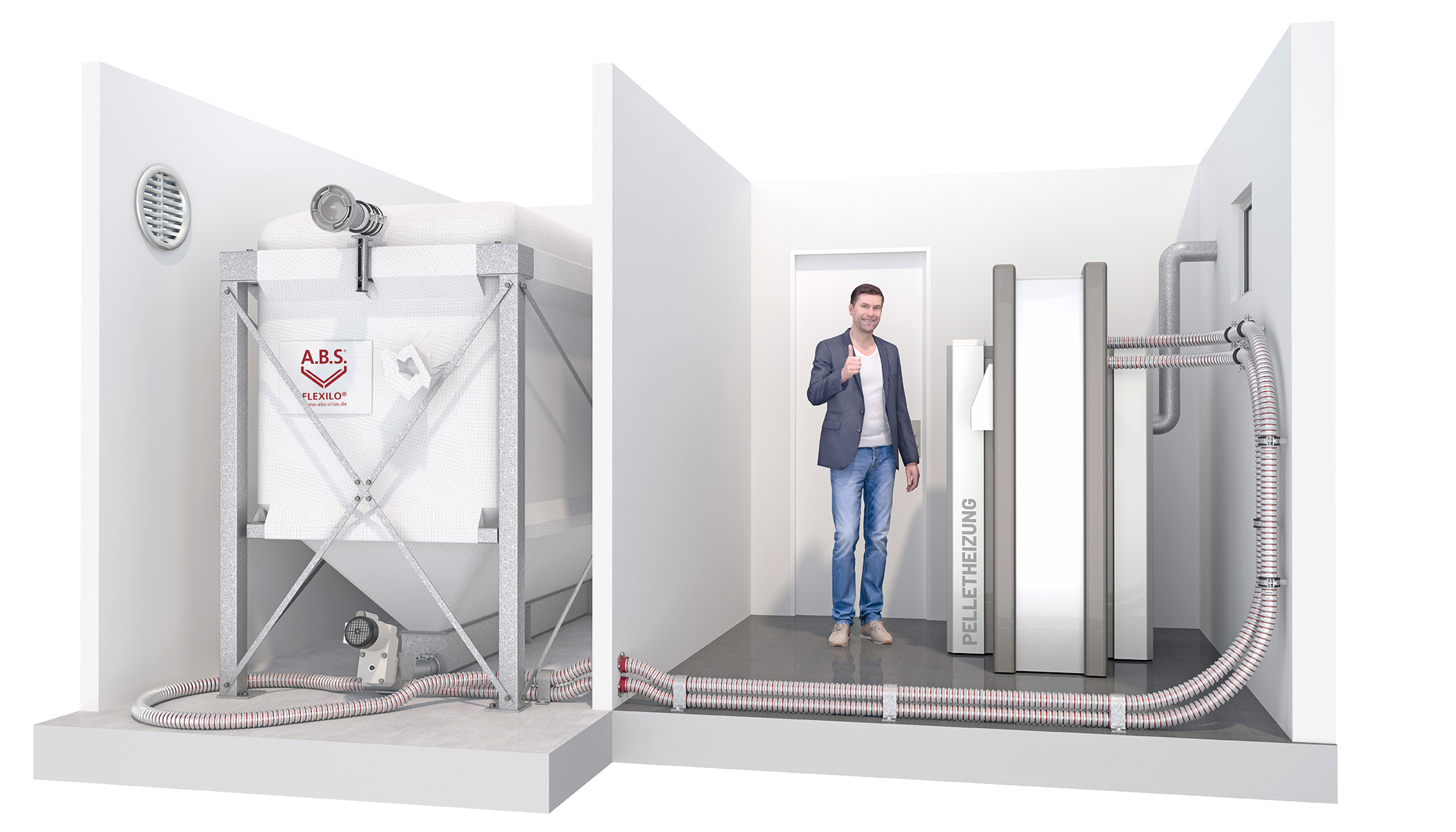

The wood pellets are delivered with a silo vehicle and blown into the flexible pellet store. When filling, the blown air escapes through the lid fabric of the silo. Therefore, forced extraction is not necessary (exhaust air opening of at least 400 cm² is required in the installation room). To maximize space utilization, the pellets are blown in horizontally above the support bar. The flexible walls and built-in impact protection ensure that the wood pellets are filled gently. The appropriate filling system is included in the scope of delivery of every A.B.S. silo, but may differ depending on the silo variant.

Ab einer Gestellbreite von 2,5 m werden A.B.S.-Silos mit

2 Befüllleitungen ausgestattet.

Standard position of the filling line for rectangular silos

With rectangular silos, the filling line is located on the narrow side as standard. From a frame width of 2.5 m, 2 filling lines are included in the scope of delivery.

Important things at a glance:

- Use quality pellets in accordance with the internationally valid standard ISO 17225-2 or EN plus. Further information can be found at www.enplus-pellets.de

- No forced extraction necessary (exhaust air opening of at least 400 cm² required in the installation site)

- The permanently installed filling line and the filling hose of the silo vehicle should not exceed 30 m

- Moisture must be prevented from entering the filling pipe

- The filling coupling must be accessible and easy for the tanker driver to reach (without using ladders, etc.).

- Pay attention to the position of the filler necks – see above.

- The manual filling nozzle should be accessible

- Make sure you fill it properly!

Pellets stored properly. Optimal use of space.

A.B.S. FLEXILO® FOR PELLET STORAGE.

Not with silos made of technical textiles, such as the Flexilo® from A.B.S.: Made from high-strength high-tech fabric, they are perfectly tailored to the sensitive bulk material, are dust-tight and permanently electrostatically dissipative. Flexible walls and built-in impact protection ensure gentle filling.

Thanks to the air-permeable fabric, no condensation forms during temperature fluctuations. Delivered compact, your A.B.S. Fabric silo even through the narrowest door and can be set up there quickly and easily – in order to safely store and have ready the fuel for sustainable energy in the future.

Joachim Heimberger

Aktuelle Förderung ab 01.01.2024

Seit dem 01. Januar 2024 ist die Förderrichtlinie „Bundesförderung für effiziente Gebäude-Einzelmaßnahmen (BEG – EM)“ in Kraft. Anträge für einzelne Effizienzmaßnahmen können weiterhin gestellt werden. Der Heizungstausch kann ab sofort beauftragt und der Förderantrag nachgereicht werden. So profitieren Sie schon jetzt von den neuen Fördersätzen.

Weitere Informationen unter www.energiewechsel.de/beg.

Antworten auf häufige Fragen zur Bundesförderung für effiziente Gebäude erhalten Sie beim Bundesministerium für Wirtschaft und Klimaschutz unter diesem Link hier.

Voraussetzungen & Rahmenbedingungen:

- Bei der Installation eines Pelletkessels ist ein Pufferspeicher-Volumen von mindestens 30 Litern je kW Nennwärmeleistung ist installieren, ebenso wie ein Wärmemengenzähler zur Erfassung der erzeugten Wärme.

- Keine Vorgabe zur Anzahl der Pufferspeicher und zum Aufstellort: Die Vorgaben zum Pufferspeicher beziehen sich nur auf das Pufferspeichervolumen.

- Das Mindestinvestitionsvolumen beträgt bei Einzelmaßnahmen 2.000 € (brutto)

- Es muss ein hydraulischer Abgleich nach Verfahren B durchgeführt werden (Verfahren A ist nicht zulässig)

- Verpflichtende Beratung vor Einbau einer Pelletheizung

-> Mit dem neuen GEG hat beim geplanten Einbau von Heizungsanlagen mit festem, flüssigem oder gasförmigem Brennstoff (Pellets, Öl, Gas etc.) ist eine Beratung durch einen Fachhandwerker verpflichtend vorgeschrieben.

-> Das durchgeführte Beratungsgespräch muss mit einem Formblatt bestätigt werden - Liste der förderfähigen Biomasseanlagen beachten. Die Liste finden Sie hier bei der BAFA

- Regelung und Zündung: Pellet- und Hackschnitzelanlagen: Sie müssen mit einer Leistungs- und Feuerungsregelung, sowie einer automatischen Zündung ausgestattet sein.

- Anforderungen an die Energieeffizienz: Der „jahreszeitbedingte Raumheizungsnutzungsgrad“ ƞ s (= Eta s) gemäß Öko-Design-Richtlinie förderfähiger Biomasseanlagen muss ab 2023 mindestens 81 Prozent erreichen.

TIPP: Wenn Sie sich als Energie-Effizienz-Experte registrieren wollen, können Sie das unter diesem Link tun: https://fachunternehmen.energie-effizienz-experten.de/

Auskünfte zum Förderprogramm: Auskünfte zur BEG erhalten Antragsteller und SHK-Betriebe bei den folgenden Stellen:

- Hotline KfW: zur BEG-Heizungsförderung: 0800 – 539 90 10, für andere BEG-Themen: 0800 – 53990 02, infocenter@kfw.de

- Auskünfte zur Förderung für Errichtung, Umbau oder Erweiterung von Gebäudenetzen:

Für Fragen, Probleme und Anregungen ausschließlich zu Errichtung, Umbau oder Erweiterung von Gebäudenetzen kann die Mailadresse wnet@bafa.bund.de genutzt werden. - Energie-Info-Center (EIC) des BAFA: 06196 – 908-1625; beg@bafa.bund.de

- Förderberatung Energieeffizienz des BMWK (für allgemeine Auskünfte zum Förderprogramm): 0800 – 0115 000

- BEG-Beraternetzwerk:

Die Mailadresse beg-beraternetzwerk@bafa.bund.de kann nicht nur von Energieeffizienzexperten, sondern auch von Verbänden der bei der BEG-Förderung involvierten Branchen zur Klärung von offenen Auslegungs- und Verfahrensfragen genutzt werden, seit 2024 aber nicht mehr für Förderanträge zur Heizungstechnik. Je öfter diese Möglichkeit für längst beantwortete Standardfragen von Antragstellern und SHK-Betrieben genutzt wird, die von den Betroffenen mittels der vorliegenden Informationsquellen geklärt werden können, desto schlechter funktioniert dieser „privilegierte Zugang“ zur Klärung wirklich neuer Auslegungs- und Verfahrensfragen.

Das gibt es neben der BEG EM Förderung:

Fast alle Bundesländer bieten ergänzende Fördergrogramme für Gebäudemodernisierungen.

Der DEPI (Deutsches Pelletinstitut) bietet hierzu eine Zusammenstellung: https://depi.de/de/foerderprogramme/foerderprogramme-nach-bundeslaendern

Unabhängige und qualifizierte Experten – bei der KfW auch „Energieeffizienz-Experten“ genannt – sind die richtigen Ansprechpartner, wenn es um eine energetische Sanierung geht. Sie planen die Sanierung, überwachen die Arbeiten und sichern die hohe Qualität aller Maßnahmen. Zunächst macht Ihr Energieffizienz-Experte eine Bestandsaufnahme des energetischen Ist-Zustands Ihrer Immobilie.

Auf Basis der Bestandsaufnahme erarbeiten die Energieeffiziens-Experten dann Vorschläge, wie Sie Schwachstellen beseitigen können und welche Kosten damit verbunden sind.

Nachdem Sie sich für bestimmte Sanierungsmaßnahmen entschieden haben, geht es an die detaillierte energetische Fachplanung. Auf dieser Grundlage können Sie dann Gewerke ausschreiben und Angebote einholen. Bei Bedarf erhalten Sie auch Hilfe, wenn es darum geht, die Angebote zu prüfen.

Bitte beachten Sie: Reichen Sie Ihren Antrag ein, bevor Sie das Unternehmen beauftragen und bevor die Arbeiten losgehen. Planungs- und Beratungsleistungen können Sie schon vor Ihrem Antrag in Anspruch nehmen.

Achtung: Die BAFA-Förderung für Energieberatung kurzfristig auf 50 Prozent gekürzt.

Aufgrund der hohen Anzahl an Förderanträgen für eine qualifizierte Energieberatung hat das BAFA die Zuschüsse ab dem 7.8.2024 von 80 auf 50 Prozent gekürzt. Somit sind maximal 650 Euro für Ein- und Zweifamilienhäuser Zuschuss möglich. Bei Mehrfamilienhäusern ab drei Wohneinheiten beläuft sich der Betrag auf 850 Euro und bei WEG auf einmalig 250 Euro für die Erläuterung der Beratungsergebnisse im Rahmen einer Eigentümerversammlung. Die Zuschüsse für Einzelmaßnahmen in der Bundesförderung für effiziente Gebäude (BEG) bleiben in gleicher Höhe erhalten. Es ändert sich auch nichts daran, dass der Fördersatz für energetische Sanierungsmaßnahmen nach einer Energieberatung mit einem iSPF von 15 auf 20 Prozent steigt.

Energieberater in Ihrer Nähe finden:

Die Energie-Effizienz-Experten oder das deutsche Energieberater-Netzwerk unterstützen Sie bei der Suche nach einem geeigneten Energieberater in Ihrer Nähe.

Detaillierte Infos erhalten Sie auch in der Förderfibel des Deutschen Pelletinstituts (DEPI).

Mit der Förderfibel bietet das Deutsche Pelletinstitut (DEPI) Verbrauchern einen übersichtlichen Leitfaden durch den Förderdschungel der Erneuerbaren Wärme. Die Informationsbroschüre gibt leicht verständliche Antworten auf alle Fragen zu den bestehenden Fördermöglichkeiten für Pellet- und Holzfeuerungen durch Bund, Länder und Kommunen.

Link zur Förderfibel: https://depv.de/p/Broschure-Forderfibel-qkHFYruRQVE1HYuqZgtEcj

Fördermittelrechner für Holzkessel und wasserführende Pelletkaminöfen

Stand Januar 2023: Der Fördermittelrechner kann für die meisten Förderprojekte, die seit dem 1. Januar 2023 begonnen werden, genutzt werden.

Noch nicht vollständig integriert ist die Förderung der Errichtung von Gebäudenetzen. Die Aktualisierung ist in Arbeit. Wir bitten noch um etwas Geduld.

Ab 2024 sind Förderanträge für neue Wärmeerzeuger (u.a. für neue Holzheizungsanlagen) bei der Kreditanstalt für Wiederaufbau (KfW) zu stellen, nicht mehr beim Bundesamt für Wirtschaft und Ausfuhrkontrolle (BAFA). Eine Antragstellung wird dort für Eigentümer selbstgenutzter Einfamilienhäuser voraussichtlich ab dem 27. Februar 2024 möglich sein, für andere Eigentümer bis zum Sommer. Aufgrund der vorübergehend möglichen Antragstellung nach Vorhabenbeginn muss man mit dem Heizungstausch trotzdem nicht warten, bis eine Antragstellung wieder möglich ist.

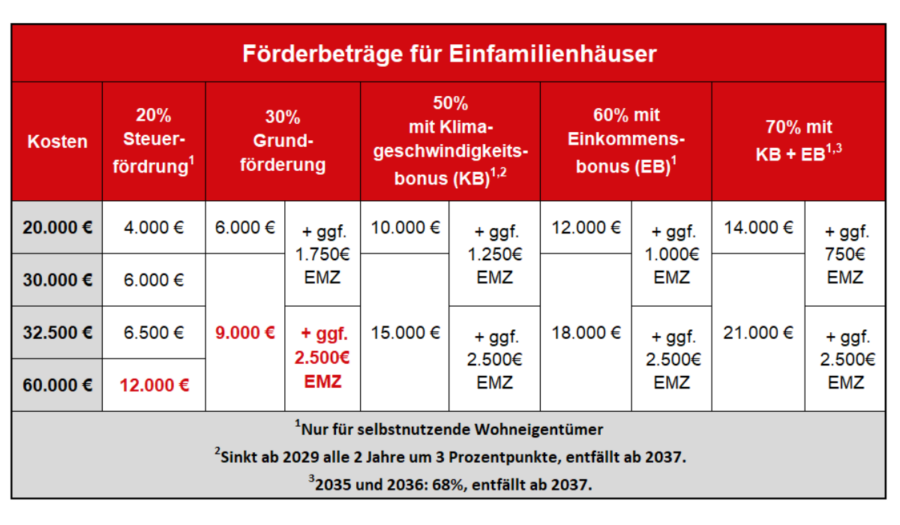

Die Grundförderung

Wenn Sie jetzt auf eine klimafreundliche Heizung mit mindestens 65% erneuerbaren Energien umsteigen, erhalten Sie hierfür 30% Grundförderung.

ACHTUNG: Die Grundförderung und die verschiedenen Bonusförderungen lassen sich miteinander kombinieren – bis zu einem Fördersatz von maximal 70%.

Bei der Grundförderung gibt es keine Kombinationspflicht! Diese Förderung steht allen privaten Eigentürmern, Vermietern, Unternehmen, organisationen, Kommunen und Contractoren in allen Wohngebäuden zu. Der Raumheizungs-Jahresnutzungsgrad soll 81% betragen.

Der Klimageschwindigkeitsbonus (KB)*

Man erhält den Bonus nur, wenn man eine funktionstüchtige: Öl-, Kohle-, Gas-Etagen-, Nachtspeicherheizung oder eine mindestens 20 Jahre ö – alte Gasheizung oder Biomasseheizung austauscht und die alte Heizung fachgerecht demontiert und entsorgt wird.

- Kombinationspflicht mit bestehender oder neuer Photovoltaik- oder Solaranlage

- Folgende Nachweise sind einzusenden: – Meldebescheinigung / Meldebestätigung – Grundbuchauszug: Meldebescheinigung / Meldebestätigung & Grundbuchauszug

- Gilt bei Austausch von: Öl-, Kohle-, Gasetagen- und Nachtspeicherheizungen & Gasheizungen Holzheizungen, wenn bei Antragsstellung mind. 20 Jahre alt

- Begrenzung auf Wohngebäude und selbstgenutze Eigentümer d. h. im Grundbuch eingetragen & beim Einwohnermeldeamt als Bewohner gemeldet

- Die Trinkwassererwärmung muss dabei bilanziell abgedeckt sein.

Gilt nicht für:

- Vermietungen,

- unentgeltliche Überlassungen

- Nießbrauch der Wohnung

*Der Bonus ist zeitlich gestaffelt:

- bis Ende 2028: 20%

- bis Ende 2030: 17%

- bis Ende 2032: 14%

- bis Ende 2024: 11%

- bis Ende 2036: 8%

- Ab 2037 entfällt der Bonus.

Einkommensbonus (EB)

Voraussetzungen:

- selbstnutzende Wohneigentümer

- zu versteuerndes Haushaltseinkommen unter 40.000€

- Einkommenssteuerbescheide für Jahr 2 und 3 vor der Antragstellung (2024 also für 2021 und 2022)

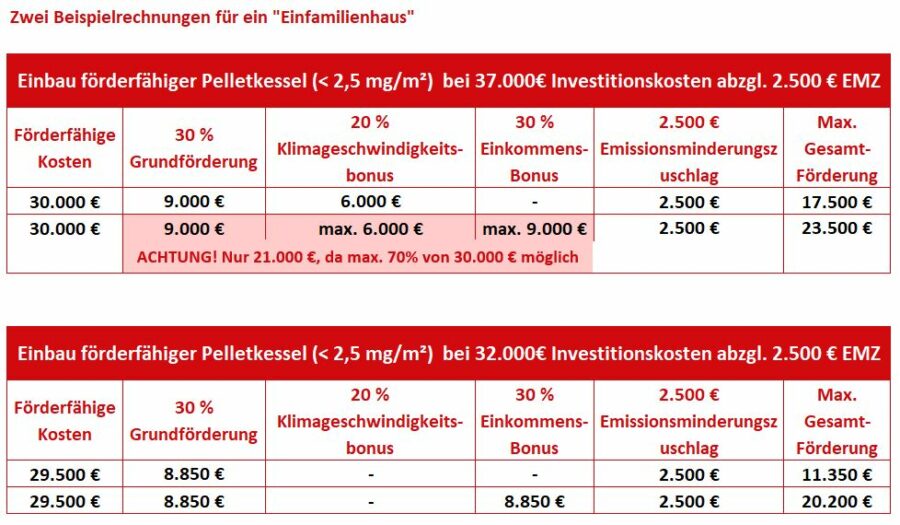

Emissionsminderungs-Zuschlag (EMZ)

Beim Heizungstausch:

- Bei Biomasseanlagen pauschal 2.500€ bei Emissionsgrenzwert für Staub von 2,5mg/m³

- keine Kappung durch Höchstfördersätze

- pauschaler Abzug von den förderfähigen Kosten

Bitte beachten Sie: Der Emissionsminderungszuschlag wird immer zuerst von der Höhe der Förderfähigen Kosten abgezogen. Entscheidend ist also die Höhe der “Förderfähigen Kosten”.

Die förderfähigen Gesamtkosten müssen nach Abzug mindestens 300 Euro (brutto) betragen.

Wenn diese >= 32.500 € liegen, dann führt der Abzug des Emissionsminderungszuschlag von 2.500 € dazu, dass die maximalen Förderkosten von 30.000 € angesetzt werden und man kann bei Erhalt aller Boni auf eine max. Fördersumme von 23.500 € kommen (untere Beispiele in der nachfolgenden Tabelle)

Wenn diese < 32.500 € liegen, reduziert sich die maximale Fördersumme von 23.500 € entsprechend unter 23.500 € (oberes Beispiel in der nachfolgenden Tabelle)

Förderfähige Kosten:

Die förderfähigen Kosten umfassen alle notwendigen Maßnahmen für die Vorbereitung und Umsetzung des Heizungseinbaus und alle damit zusammenhängenden Maßnahmen zur Erhöhung der Energieeffizienz der gesamten Heizungsanlage: Dazu gehören folgende Anlagenkosten und Kosten für Umfeldmaßnahmen (jeweils inkl. Installation und Inbetriebnahme):

Wie hoch Ihre Fördersumme ist, hängt auch von den förderfähigen Kosten ab. Für den Heizungstausch in einem Einfamilienhaus betragen diese maximal 30.000 €. So können Sie bis zu 23.500 € Förderung für Ihre neue Heizung bekommen. Die Förderung kann nur zugesagt werden, solagne die Fördermittel nicht ausgeschöpft sind.

Das „Infoblatt zu den förderfähigen Maßnahmen und Leistungen“ enthält einen Überblick, welche Maßnahmen bei der Sanierung von Wohn- und Nichtwohngebäuden gefördert werden können. Auch nicht förderfähige Investitionskosten werden aufgelistet. Das Dokument wird derzeit überarbeitet und steht Ihnen in Kürze wieder zur Verfügung.

Wird die Maßnahme nicht durch ein Fachunternehmen durchgeführt, sondern als private Eigenleistung erbracht, werden nur die direkt mit der energetischen Sanierungsmaßnahme verbundenen Materialkosten gefördert. Voraussetzung dafür ist, dass eine Experte für Energieeffizienz oder ein Fachunternehmer die fachgerechte Durchführung sowie die korrekte Angabe der Ausgaben für das Material bestätigt.

PLUS: BEG Einzelmaßnahmen: Kreditförderung

Für alle Einzelmaßnahmen in der BEG EM wird für seit dem 1. Januar 2024 gestellte Förderanträge ein Ergänzungskredit von der KfW erhältlich sein. Dieser wird die gesamten Kosten der Maßnahme finanzieren, offenbar auch die Kosten, die ggf. über den Höchstbetrag förderfähiger Kosten hinausgehen.

- als Ergänzungskredit der KfW

- BEG-Förderzusage ist Voraussetzung. 2 Anträge sind nötig: Förderantrag und Kreditantrag (bei Hausbank)

- Antragsberechtigung: alle Förderantragssteller für Einzelmaßnahmen

- Zinsvergünstigung von max. 2,5 %: nur für selbstnutzende Eigentümer mit bis zu 90.000 € zu versteuerndem Haushaltseinkommen

- Die Kreditsumme beträgt für alle gleichzeitig förderfähigen Einzelmaßnahmen zusammen bis zu 120.000 € pro Wohnung

- Der Antrag ist vor Beginn der Bauarbeiten und innerhalb von 12 Monaten nach der Förderzusage zu stellen

- Zinsbindungsfrist: Die Zinsbindungsfrist liegt bei 5 oder 10 Jahren.

- Laufzeit: Die Laufzeit von Ergänzungskrediten beträgt mindestens 4 und maximal 35 Jahre.

Hier finden Sie ein Merkblatt und weitere Infos zum Ergänzungskredit.

Silos for Wood pellets

Advantages of wood pellet silos

Low maintenance and friendly

Low maintenance and friendly

Made from high-strength high-tech fabric

Made from high-strength high-tech fabric

Fill level can be visually recognized - even without measuring technology

Fill level can be visually recognized - even without measuring technology

Cost-effective storage with optimal use of space

Cost-effective storage with optimal use of space

Simple and quick assembly – changing locations is no problem

Fast and safe delivery

Individual filling and discharge options

No condensation forms during temperature fluctuations

7-fold security on seams and fabric

Easy and dust-free filling

Where would you like it to be?

Flexilo® placement options.

Videos of our wood pellet silos

[/toggle]

REFERENCES

Implement storage systems.

Find solutions that work.

Get involved and think for yourself.

These are our strengths – since 1984.

From planning to final processing and assembly, A.B.S. with a high level of specialist knowledge and state-of-the-art manufacturing methods. You receive tailor-made silo solutions across all Flexilo® fabric silos at the highest level.

We are your partner for well thought-out and professional solutions with special requirements. This means you receive a perfectly coordinated storage system. And that for every pellet boiler, for every conveyor technology and for every structural situation, no matter how difficult

e.g. E.g. vaulted cellars, low cellar ceilings, rooms with high humidity, attics and garages.

Our references include:

- Single and multi-family homes

- Public facilities such as town halls, parsonages and churches

- Commercial and industrial buildings

- Schools, kindergartens & leisure facilities

- Clinics, old people’s and nursing homes

- Military properties

- Historic buildings and monuments

Credentials

Here you will find references with A.B.S. Silos:

Customer testimonials

Here you will find opinions from our customers who use A.B.S. Silos work:

DEPI Förderfibel downloaden

DEPI Förderfibel downloaden